- HOME

- >

- Development technology and facilities

- >

- Manufacturing processes and facilities

A thorough quality control system based on the specifications of each item

After deciding each item with the customer, including the processing methods, equipment to be used, and inspection methods, we manufacture BRITEN TUBE under a complete quality control system.

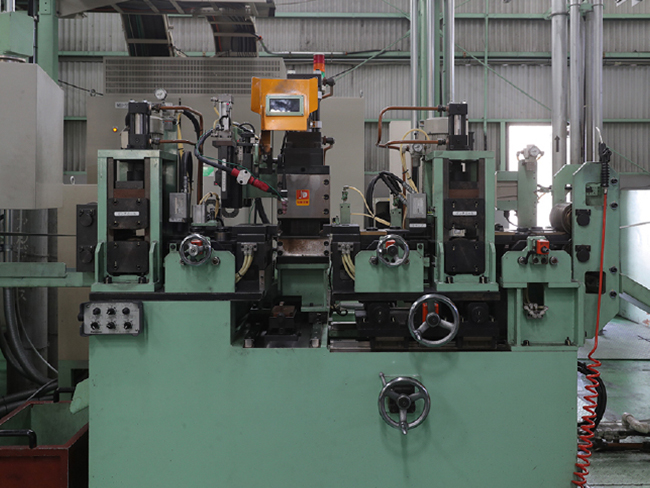

Pipe-making process

Production line for seam-welded pipe

- Uncoiler

- Joint welding

- Looper

- Molding

- High-frequency induction welding

- Cooling

- Shaping

- Eddy current flow detector

- Correction

- Cutting

- Edge finishing

- Final product

Production line for TIG pipe

- Uncoiler

- Molding

- Automated arc welding

- Cutting

Pipe In Coil

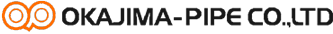

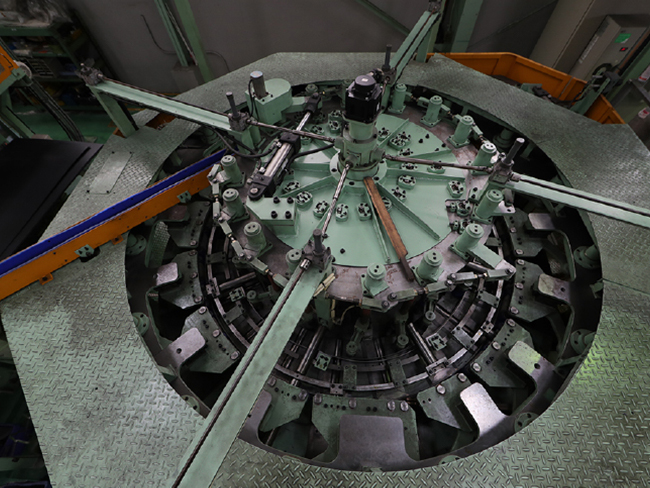

Drawing process

- Swaging

- Drawing

- Annealing

- Correction

- Cutting

- Final product

Cutting process

Other processes

Heat treatment (non-oxidation annealing furnace, bright annealing furnace)

- Anti-oxidation annealing furnace

- Bright annealing furnace

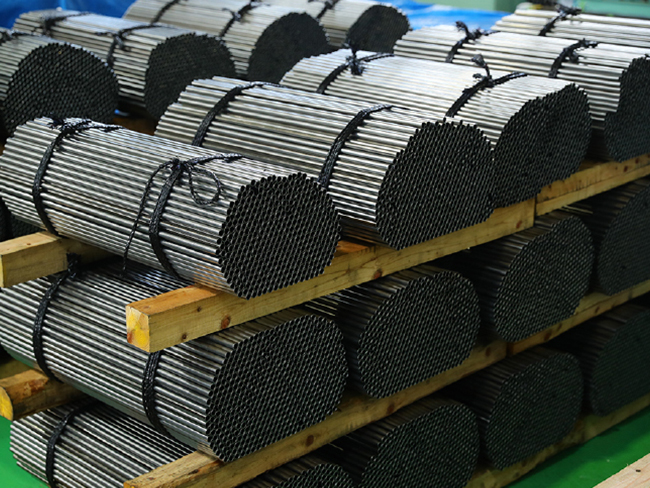

Product packaging

- Long pipe

- PIC

- Cutting

Inspection process

Inspection

Other equipment

Humidified multi-level warehouse

Power generation equipment

Shipping